Vacuum Forming Light Box Production Process Video in workshop:

Vacuum Forming Light Box can be outdoor usage, double sided, waterproof, warmly welcomed for brand sign advertising & promotion, will be usually seen in front of bank, chain shops, supermarkets, etc.

As Vacuum forming light box with different shapes mentioned in last post: rectangle, square, oval, round, rotating, with motion, or customized, etc.

Vacuum forming light box also with different lighting: tube lighting or LED lighting. We normally suggest to use LED lighting, as lifespan long, and energy saving, environmental.

Vacuum Forming Light Box also with different materials: acrylic panel or aluminium frame panel.

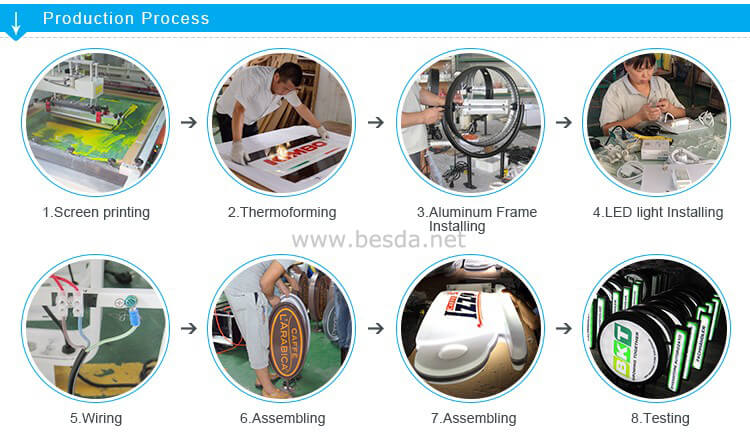

Below Vacuum Forming Light Box Aluminium Frame Production Process for your reference:

1, Vacuum Forming Light Box Waterproof Double Sides Outdoor Sign Material: